In the first half of 2024, Wuhan Institute of Building Materials actively implement the company's strategic plan, innovation and leadership, precise measures, use all favorable conditions to work hard to stabilize growth, harvesting good news constantly.

China Resources Fengkai 2×400,000 cubic meters concrete panel/block project

Concrete Panel/Block Project Passes Performance Assessment

China Resources Fengkai 2×400,000 cubic meters concrete panels/blocks project contracted by Wuhan Institute of Building Materials (WIBA), Line A passed the performance assessment and was completed and handed over to the operation, and all the data of the assessment were better than the industry indicators.

CR Fengkai 2×400,000 cubic meters concrete panels/blocks project is the first project of CR Cement's layout of aerated concrete industry, which can massively dissipate the solid waste resources of the enterprise, realize the whole process application of mine-aggregate-aggregated blocks/slabs, and set a benchmark for the domestic aerated concrete industry in terms of digital factory, intelligent manufacturing, and residual steam and heat recovery and utilization. It sets a benchmark for the domestic aerated concrete industry in terms of digital factory, intelligent manufacturing and waste steam and heat recycling.

Sinoma Chongqing New Energy-saving and Environment-friendly Wall Material Project Successfully Passed Performance and Completion Acceptance Inspection

Sinoma Chongqing 2×5 million square meters calcium silicate board project, general contracted by Wuhan Institute of Building Materials, successfully passed the performance assessment and was completed and handed over to operation.

The self-developed “1.5 generation” calcium silicate/fiber cement board production line technology has been successfully applied in Sinoma Chongqing project. The production line technology and equipment focus on the overall goal of high-quality development of the industry, solving a series of painful and difficult problems of the industry, and featuring large production capacity, high stability, green and low-carbon, intelligent and other significant characteristics. Along with a series of new technologies and new equipment successfully developed and applied, calcium silicate/fiber cement board production line green, intelligent level has been greatly improved, to promote the industry's high-quality development has played an important role in demonstrating and leading. Wuhan Institute of Building Materials will make persistent efforts, on the basis of the achievements made, continue to adhere to the innovation leadership, and promote the “2.0 generation” technology to realize the industrialization and application as soon as possible, so as to create value for customers and contribute to the development of the industry.

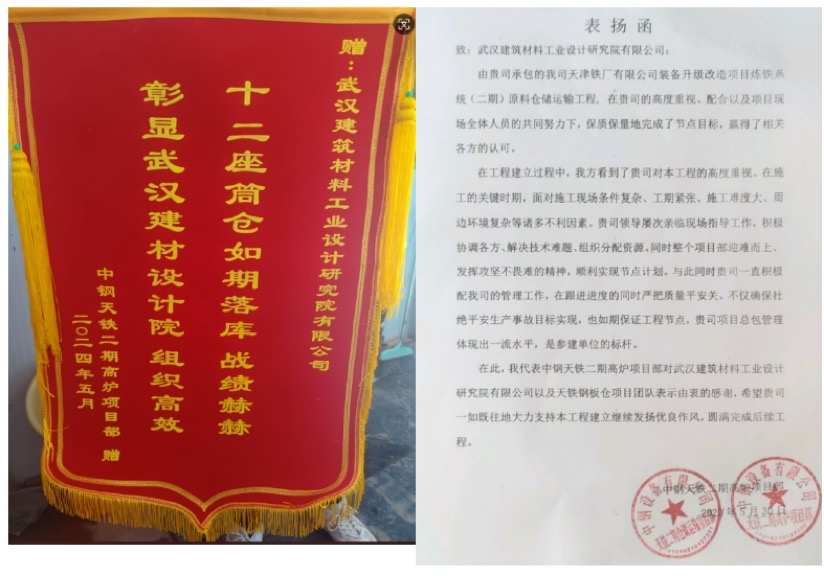

Tianjin Iron Works ironmaking system raw material storage and transportation project was successfully completed and praised by the owner.

The raw material storage and transportation project of ironmaking system of Tianjin Iron Works constructed by Wuhan Institute of Building Materials was successfully completed and praised by the owner. During the construction of the project, Wuhan Institute of Building Materials, relying on the rich experience accumulated in the industry for many years, adopted innovative design ideas and scientific management methods, overcame the influence of unfavorable factors such as narrow terrain, poor construction conditions and tight schedule, gave full play to the collective wisdom and business quality of the professional team, and completed the project construction on schedule with quality and quantity guaranteed, in order to thank Wuhan Institute of Building Materials for its contribution, the construction party sent a special In order to thank Wuhan Institute of Building Materials for its efforts, the constructor sent a silk banner and a letter of commendation.

Completion of Factory Acceptance and Delivery of Mahapan Philippines and Other Foreign Projects

Wuhan Institute of Building Materials (WIBS) actively practices the “Belt and Road” initiative, and keeps plowing into the Southeast Asian market with advanced equipment technology and design concepts. As the benchmark project of Wuhan Building Material Institute in Southeast Asia, Mahapan Philippines project has passed the factory acceptance and is now organizing the shipment. In the future, Wuhan Institute of Building Materials will actively gather advantageous resources, continue to carry out technological innovation, and strive to broaden the overseas market.

Wuhan Institute of Building Materials will continue to uphold the concept of “honesty, pragmatism, refinement and innovation”, continue to forge ahead in the field of new building materials, energy saving and environmental protection, and contribute its strength to local construction and regional development.